Basic Guide to Communication Port Security v2.0

1. Communication Ports Overview

The following network communication is provided in Rainbow Robotics' Robot-Control Box.

- Networks for robot control and data collection, etc.

- Robot Control: Port number 5000

- Robot Data/Status Acquisition: Port number 5001

- Network for industrial communication and general data transmission and reception

- Modbus TCP: Port number 502

- Misubishi MC Comm.: User defined port number

- LS Elec. XGT Comm.: Port number 2004

- OMRON FINS Comm.: User defined port number

- SIEMENS S7 Comm.: Port number 102

- HMI MemLink Comm.: User defined port number

- General TCP/IP Comm.: User defined port number

As mentioned above, ports 5000 and 5001 are always open, and the rest of the data network ports are available only when the user explicitly configures/programs them.

2. Communication Security

In Chapter 1, the ports required for security are ports 5000 and 5001.

This is because the rest of the data ports are used only if the user has to explicitly use that function.

Since ports 5000 and 5001 are always open ports, user can configure network security in the following two ways.

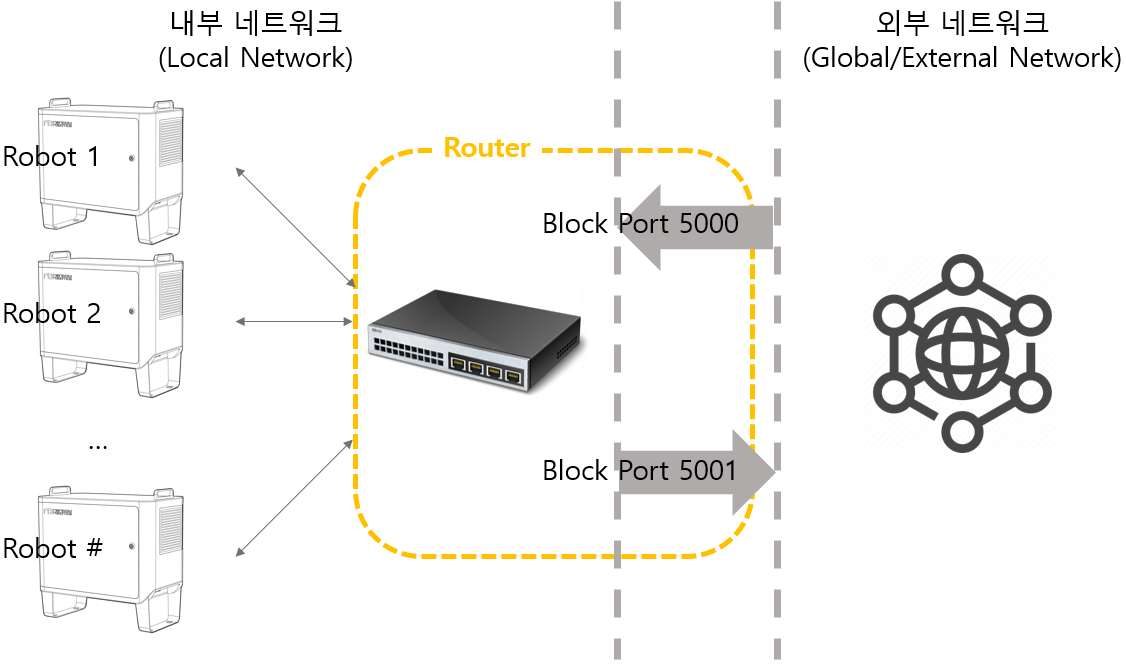

2.1 Block ports 5000/5001 from router/hub level to robot system

- This is the simplest and surest way.

- This is a method of blocking ports at the router level that relays the internal network and external network of the automation system. (Block port forwarding)

- This is a method that blocks the 5000/5001 ports coming from the outside.

2.2 Block access through software key/grammar

- Even if the port is not blocked in the same way as in 1) above, a prescribed key and grammar are required to receive control/data through the 5000/5001 port.

- Through this, if an unauthorized key or unspecified grammar is accessed from the outside, the robot stops working and the communication does not affect the system.

3. Others

The table below shows the usage categories of functions/networks for sending/receiving data.

| Manufacturer | Communication | Feature |

|---|---|---|

| SIEMENS | S7 Protocol | Server = PLC, Client = Robot |

| Modbus TCP Master | Client(Master) = Robot, Server(Slave) = PLC | |

| Modbus TCP Slave | Client(Master) = PLC, Server(Slave) = Robot | |

| RS232/485 | General Serial communication | |

| TCP/IP | General TCP/IP communication | |

| OMRON | FINS | Server = PLC, Client = Robot |

| Modbus TCP Master | Client(Master) = Robot, Server(Slave) = PLC | |

| Modbus TCP Slave | Client(Master) = PLC, Server(Slave) = Robot | |

| RS232/485 | General Serial communication | |

| TCP/IP | General TCP/IP communication | |

| MITSUBISHI | MC Protocol 1E-Binary | Server = PLC, Client = Robot |

| MC Protocol 3E-Binary | Server = PLC, Client = Robot | |

| Modbus TCP Master | Client(Master) = Robot, Server(Slave) = PLC | |

| Modbus TCP Slave | Client(Master) = PLC, Server(Slave) = Robot | |

| RS232/485 | General Serial communication | |

| TCP/IP | General TCP/IP communication | |

| LS ELEC. | XGT Protocol | Server = PLC, Client = Robot |

| Modbus TCP Master | Client(Master) = Robot, Server(Slave) = PLC | |

| Modbus TCP Slave | Client(Master) = PLC, Server(Slave) = Robot | |

| RS232/485 | General Serial communication | |

| TCP/IP | General TCP/IP communication | |

| PROFACE | Memory Link | Server = HMI, Client = Robot |

| M2I-TOP | Memory Link | Server = HMI, Client = Robot |

Rainbow Robotics

Rainbow Robotics