RB UI Script v6.10

1. Variable Types and Declaration

The UI Script of Rainbow Robotics supports the following data types.

- var : Stores a single number.

- arr : Stores the multiple number array. (up to 20 lengths)

- str : Stores string element.

- point, pnt : Stores posture (x, y, z, Rx, Ry, Rz) information.

- joint, jnt : Stores joint angles (J0, J1, J2, J3, J4, J5).

- vec : A vector that manages numbers.

(Please refer to Chapter 10 separately for number / string vectors.)

An example of a variable declaration is shown below.

1.1 var

Example :

var my_val # Assign variable without initial value (initial value is 0)

var my_val = 1 # Assign variable with initial value1.2 arr

Example :

arr my_arr # Assign array without initial value (initial value is {0, 0, … , 0})

arr my_arr = {1, 2, 3} # Assign array with initial value1.3 str

Example :

str my_str # Assign string without initial value (initial value is “”)

str my_str = “Hello” # Assign string with initial value1.4 point, pnt

Example :

point my_point # Assign point without initial value (initial value is {0, 0, 0, 0, 0, 0})

point my_point = {100, 200, 300, 90, 0, 90} # Assign point with initial value

pnt my_point = {50, 100, 100, 90, 0, 0} # Assign point with initial value1.5 joint, jnt

Example :

joint my_joint # Assign joint without initial value (initial value is {0, 0, 0, 0, 0, 0})

joint my_joint = {0, 0, 0, 90, 0, 0} # Assign joint with initial value

jnt my_joint = {30,0,0,90,0,0} # Assign joint with initial value1.6 Abbreviations

Abbreviations used in this document are as follows.

| Abbreviation | |

|---|---|

| v | variable type (var) |

| a | Array type (arr) |

| s | String type (str) |

| P | Point type (pnt) |

| J | Joint type (jnt) |

1.7 Point type and Joint type

Point type and Joint type variables can be used as temporary variables without names.

- Temporary Point type : pnt[x, y, z, Rx, Ry, Rz]

- Temporary Joint type : jnt[J0, J1, J2, J3, J4, J5]

These temporary variables can be used immediately without a separate name declaration, and can be utilized as follows.

- Method 1 : This is an example of declaring a separate variable and using it in a function.

- Method 2 : This is an example of using the temporary variable as a function call argument without declaring a variable separately.

Method 1 :

jnt my_angle = {0,0,90,0,90,0} # Assign joint type with name ‘my_angle’.

move_j(my_angle, 60, 80) # Use ‘my_angle’ as an input argument of function ‘move_j’.

pnt my_point = {100, 200, 300, 90, 0, 0} # Assign point type with name ‘my_point’.

move_l(my_point, 20, 5) # Use ‘my_point’ as an input argument of function ‘move_l’Method 2 :

move_j(jnt[0,0,90,0,90,0], 60, 80) # temporary joint type is used as an input argument of function ‘move_j’.

move_l(pnt[100,200,300,90,0,0], 60, 80) # temporary point type is used as an input argument of function ‘move_l’.The above examples are examples using move_j(J, v, v) and move_l(P, v, v) functions.

For more information about these functions, see Chapter 7. Motion Functions.

1.8 UI Script examples

Rainbow UI Script can be used as follows

Example 1. Simple math operation

var a = 1 # Assign variable, name is ‘a’ and init-value 1

var b = 2 # Assign variable, name is ‘b’ and init-value 2

var c # Assign variable, name is ‘c’

c = a *b + 5 + sqrt(4) # ‘c’ stores the result value of 9Example 2. Basic movement

joint target_angle = {0, 0, 90, 0, 90, 0} # Assign joint type, name is ‘target_angle’

move_j(target_angle, 60, 80) # move arm with ‘move_j’, speed/acceleration = 60/80

target_angle[0] = target_angle[0] + 45 # Add 45 degrees to the axis-0 value from the previous value.

move_j(target_angle, 60, 80) # move arm with ‘move_j’, speed/acceleration = 60/80

target_angle[0] = target_angle[0] + 45 # Add 45 degrees to the axis-0 value from the previous value.

move_j(target_angle, 60, 80) # move arm with ‘move_j’, speed/acceleration = 60/80

move_j(jnt[0, 0, 0, 0, 0, 0], 60, 80) # move arm with ‘move_j’ to zero-home postureExample 3. String function

str my_text = “123.78” # Assign string with name ‘my_text’

var result_1 = to_num_int(my_text) # 123 is stored in variable ‘result_1’

var result_2 = to_num(my_text) # 123.78 is stored in variable ‘result_2’

var result_3 = round( to_num(my_text) ) # 124 is stored in variable ‘result_3’

str my_text2 = “abc” # Assign string with name ‘my_text2’

str my_text3 = my_text + my_text2 # “123.78abc” is stored in string ‘my_text3’1.9 Operators

The following comparison operators and logical operators can be used.

1.9.1 Comparison operators

- A >= B

- 1 (True) if the left side is greater than or equal to the right side, otherwise 0 (False)

- A <= B

- 1 (True) if the right side is greater than or equal to the left side, otherwise 0 (False)

- A == B

- 1 (True) if the left and right sides are equal, otherwise 0 (False)

- A != B -1 (True) if the left and right sides are not-equal, otherwise 0 (False)

1.9.2 Logical operators

A && B

A and B

A AND B

A And B

- 1 (True) only if both the left and right sides are True, otherwise 0 (False)

A || B

A or B

A OR B

A Or B

- 1 (True) if either of the left and right sides is True, 0 (False) if both values are False

1.9.3

TRUE and FALSE used in comparison/logical operation are matched with the following values.

True = TRUE = true = 1

False = FALSE = false = 0

Therefore, the following two examples become the same expression.

Example 1.

if (SD_SOCK_IS_OPEN_0 == True){

// something to do

}Example 2.

if (SD_SOCK_IS_OPEN_0 == 1){

// something to do

}1.10 Units

The Script grammar of Rainbow Robotics uses the following units.

- Angle : Degree

- Position : mm (0.001m)

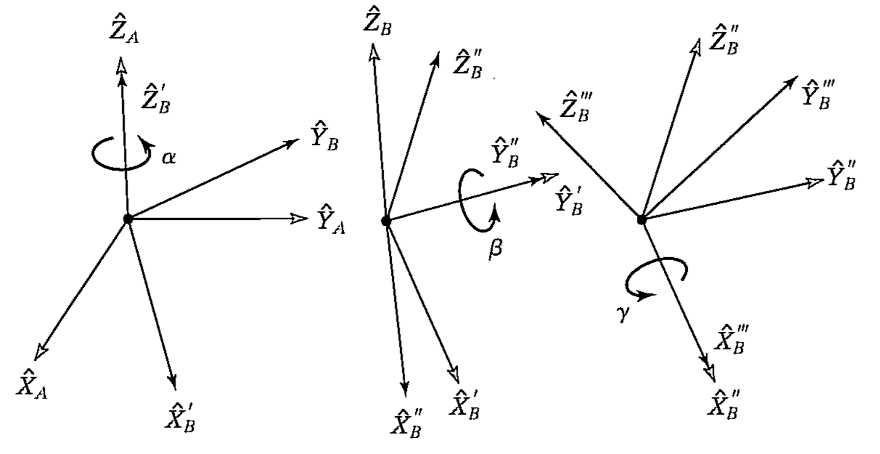

The following rotation notation is used in the script grammar and notation of Rainbow Robotics.

- Z-Y’-X’’ Euler angle (Degree)

2. Math Functions

2.1 v = cos(v)

Trigonometric function Cosine operation function.

Input :

Single variable type or constant number

v: variable type or number (Unit: radian)Return :

v : return single number

Example :

var my_result = cos(45*D2R) # my_result = 0.70712.2 v = cosd(v)

Trigonometric function Cosine operation function.

Input :

Single variable type or constant number

v: variable type or number (Unit: degree)Return :

v : return single number

Example :

var my_result = cosd(45) # my_result= 0.70712.3 v = sin(v)

Trigonometric function Sine operation function.

Input :

Single variable type or constant number

v: variable type or number (Unit: radian)Return :

v : return single number

Example :

var my_result = sin(30*D2R) # my_result= 0.52.4 v = sind(v)

Trigonometric function Sine operation function.

Input :

Single variable type or constant number

v: variable type or number (Unit: degree)Return :

v : return single number

Example :

var my_result = sind(30) # my_result= 0.52.5 v = tan(v)

Trigonometric function Tangent operation function.

Input :

Single variable type or constant number

v: variable type or number (Unit: radian)Return :

v : return single number

Example :

var my_result = tan(45*D2R) # my_result=12.6 v = tand(v)

Trigonometric function Tangent operation function.

Input :

Single variable type or constant number

v: variable type or number (Unit: degree)Return :

v : return single number

Example :

var my_result = tand(45) # my_result=12.7 v = acos(v)

Trigonometric function Inverse-Cosine operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number (Unit: radian)

Example :

var my_result = acos(-1) # my_result= PI (3.141592)2.8 v = acosd(v)

Trigonometric function Inverse-Cosine operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number (Unit: degree)

Example :

var my_result = acosd(-1) # my_result=1802.9 v = asin(v)

Trigonometric function Inverse-Sine operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number (Unit: radian)

Example :

var my_result = asin(1) # my_result= 1.57082.10 v = asind(v)

Trigonometric function Inverse-Sine operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number (Unit: degree)

Example :

var my_result = asind(1) # my_result= 902.11 v = atan(v)

Trigonometric function Inverse-Tangent operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number (Unit: radian)

Example :

var my_result = atan(1) # my_result= 0.78542.12 v = atand(v)

Trigonometric function Inverse-Tangent operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number (Unit: degree)

Example :

var my_result = atand(1) # my_result= 452.13 v = atan2(v, v)

Inverse trigonometric function that calculates the quadrant arc tangent.

Input :

Two variable types or constant numbers

v: y direction variable type or number

v: x direction variable type or numberReturn :

v : return single number (Unit: radian)

Example :

var my_result = atan2(1, 1) # my_result= 0.78542.14 v = atan2d(v, v)

Inverse trigonometric function that calculates the quadrant arc tangent.

Input :

Two variable types or constant numbers

v: y direction variable type or number

v: x direction variable type or numberReturn :

v : return single number (Unit: degree)

Example :

var my_result = atan2d(1, 1) # my_result= 452.15 PI

It is a constant representing the circumference (π).

Example :

var my_val = PI # my_val = 3.1422.16 R2D

Operation constant (180/PI) to convert from radian to degree.

Example :

var my_val= PI*R2D # my_val=1802.17 D2R

Operation constant (PI/180) for converting degree to radian.

Example :

var my_val= 180*D2R # my_val=3.1422.18 v = abs(v)

Calculate absolute value of input argument

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number

Example :

var my_result = abs(-5.2) # my_result= 5.22.19 v = sqrt(v)

Square root operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number

Example :

var my_result = sqrt(4) # my_result= 22.20 v = cell(v)

Rounding-up operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number

Example :

var my_result = cell(4.2) # my_result= 52.21 v = floor(v)

Rounding-down operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number

Example :

var my_result = floor(4.8) # my_result= 42.22 v = round(v)

Rounding operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number

Example :

var my_result = round(4.2) # my_result= 4

var my_result = round (4.8) # my_result= 52.23 v = log(v)

Natural logarithm (ln) operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number

Example :

var my_result = log(4) # my_result= 1.38622.24 v = log10(v)

Logarithm (log10) operation function.

Input :

Single variable type or constant number

v: variable type or numberReturn :

v : return single number

Example :

var my_result = log10(3) # my_result= 0.47712.25 v = pow(v, v)

Power operation function.

Input :

Two variable types or constant numbers

v: variable or constant that is a base of a power

v: variable or constant that is an exponent of a powerReturn :

v : return single number

Example :

var my_result = pow(2,3) # my_result= 82.26 v = rand()

Random number generator function with a uniform distribution between 0 and 1.

Input :

None.Return :

v : return single number

Example :

var my_result = rand() # my_result= 0.1315

var my_result = rand() # my_result= 0.7869

var my_result = rand() # my_result= 0.42772.27 v = arr_size(a)

Return size of array variable

Input :

a: target array variableReturn :

v: return single number

Example :

var my_size

arr my_arr = {1,2,3,4}

my_size = arr_size(my_arr) # my_size= 42.28 a = arr_sub(a, v)

Trims the source array to a given length, counting from the front.

Input :

a: target array variable

v: target sizeReturn :

a: trimmed array

2.29 a = arr_sub(a, v, v)

Trims the source array to a given length, counting from given starting point.

Input :

a: target array variable

v: starting point index

v: target sizeReturn :

a: trimmed array

2.30 a = zyzE_to_zyxE(a), a = xyzE_to_zyxE(a), a = xyxE_to_zyxE(a), a = xzxE_to_zyxE(a), a = yzyE_to_zyxE(a), a = yxyE_to_zyxE(a), a = zxzE_to_zyxE(a)

Convert Euler angles in 3by1 to Euler angles in 3by1 ZY'X''.

Input :

a: Source Euler angle array (length should be 3)Return :

a: Converted Euler angle array (ZY’X’’) (length = 3)

2.31 a = zyzE_to_R(a), a = xyzE_to_R(a), a = xyxE_to_R(a), a = xzxE_to_R(a), a = yzyE_to_R(a), a = yxyE_to_R(a), a = zxzE_to_R(a), a = zyxE_to_R(a)

Convert Euler angles of 3by1 to Rotation Matrix.

Input :

a: Source Euler angle array (length should be 3)Return :

a: Converted Rotation Matrix (length = 9)

2.32 a = RxMat(v), a = RyMat(v), a = RzMat(v)

Generates a Rotation Matrix based on the input angles. Rx, Ry, and Rz represent the respective rotation axes.

Input :

v: angle in degree unitReturn :

a: Converted Rotation Matrix (length = 9)

2.33 a = R_TCP

Returns the current TCP's Rotation Matrix.

Input :

None.Return :

a: Converted Rotation Matrix (length = 9)

2.34 a = point_to_R(P, v)

Extracts the Rotation Matrix from the input Point variable.

Input :

P: target Point variable

v: Option- 0 : X,Y,Z,Rx,Ry,Rz Point -> R

- 1 : X,Y,Z,Rz,Ry,Rx Point -> R

Return :

a: Converted Rotation Matrix (length = 9)

2.35 a = Rinverse(a), a = Rtranspose(a)

Finds the Inverse (Transpose) of the Rotation Matrix.

Input :

a: Source Rotation Matrix Array (length should be 9)Return :

a: Converted Rotation Matrix (length = 9)

2.36 a = R_x_R(a, a)

Rotation Matrix Multiplication

Input :

a: Source Rotation Matrix Array (length should be 9)

a: Source Rotation Matrix Array (length should be 9)Return :

a: Converted Rotation Matrix (length = 9)

2.37 a = R_x_V(a, a)

Rotation Matrix and Vector (3by1) Multiplication

Input :

a: Source Rotation Matrix Array (length should be 9)

a: Source Vector (length should be 3)Return :

a: Multiplied Vector (length = 3)

2.38 a = R_to_zyxE(a)

Convert Rotation Matrix into ZY’X’’ Euler angle

Input :

a: Source Rotation Matrix Array (length should be 9)Return :

a: Converted Euler angle array (length = 3)

3. String Functions

3.1 v = str_empty(s)

This function returns the presence or absence of data in a string.

Input :

Single string type variable or constant string.

s: string type variable or constant stringReturn :

v : return single number 0 or 1 (if string is empty 1, if it is not empty 0)

Example :

string my_str1 = “rainbow”

string my_str2

var my_result1 = str_empty(my_str1) # my_result1= 0

var my_result2 = str_empty(my_str2) # my_result2= 13.2 v = str_find(s, s)

A function that returns the index of a string's position within another string.

Input :

Two string type variables or constant strings.

s: reference string

s: string to find (target)Return :

v: Returns a single number corresponding to the index.

: If it does not exist, it returns -1.

Example :

string my_str1 = “rainbow_robotics”

string my_str2 = “robotics”

var my_result = str_find(my_str1, my_str2) # my_result= 83.3 v = str_len(s)

A function that returns the length of a string.

Input :

Single string type variable or constant string.

s: string type variable or constant stringReturn :

v: return single number (length of the string)

Example :

string my_str = “rainbow_robotics”

var my_result = str_len(my_str) # my_result= 163.4 s = str_sub(s, v, v)

A function that truncates a string and returns part of it.

Input :

Single string type variable or constant string, and two variable types.

s: reference string

v: starting index for truncation (variable type or number)

v: length for truncation (variable type or number)Return :

s: return truncated string

Example :

string my_str = “rainbow_robotics”

string my_result = str_sub(my_str, 3, 7) # my_result= “nbow_ro”3.5 s = str_cat(s, s)

A function that concatenates strings together.

Input :

Two string type variables or constant strings.

s: First string

s: Second stringReturn :

s: return added string

Example :

string my_str1 = “hi”

string my_str2 = “rainbow”

string my_res = str_cat(my_str1, my_str2) # my_res= “hirainbow”

string my_res2 = my_str1 + my_str2 # ’+’ operator returns same result

string my_res3 = “My name” + “ is “ + “RB!” # my_res3= “My name is RB!”3.6 v = str_cmp(s, s)

A function that compares strings with each other.

Input :

Two string type variables or constant strings.

s: single string for reference

s: single string for comparing targetReturn :

v: Returns 0 if the strings are equal, or a single non-zero number if they are different.

If the strings are not equal, compares the first unequal character and returns a single number with a value greater than zero if the base string is greater than the comparison string and less than zero if the string is less than.

Example :

string my_str1 = “hello”

string my_str2 = “hello”

string my_str3 = “hgello”

string my_str4 = “Hello”

var my_result1 = str_cmp(my_str1, my_str2) # my_result1= 0

var my_result2 = str_cmp(my_str2, my_str3) # my_result2= -2 … compare e(101) and g(103)

var my_result3 = str_cmp(my_str3, my_str2) # my_result3= 2 … compare g(103) and e(101)

var my_result4 = str_cmp(my_str1, my_str4) # my_result4= 32 … compare h(104) and (72)3.7 v = to_num(s)

Convert character (string) numbers to real-number

Input :

Single string type variable or constant string.

s: string type variable or constant stringReturn :

v: return single number

Example :

str my_string = “123.45”

var my_result = to_num(my_string) # my_result= 123.453.8 s = to_str (v), s = to_str (a), s = to_str (P), s = to_str (J)

s = to_str_raw (v), s = to_str_raw (a), s = to_str_raw (P), s = to_str_raw (J)

Convert variable/point/joint types to string type expression

Input :

Single variable type or array type or point type or joint type

v/a/P/J: variable type or array type or number or point type or joint typeReturn :

s: return string

Example :

var my_value = 123.45

str my_result = to_str(my_value) # my_result= “123.45”

point my_point = {100,200,300,90,0,0}

str my_result = to_str(my_point) # my_result=“{100,200,300,90,0,0}”

joint my_joint = {90,0,0,90,0,0}

str my_result = to_str(my_joint) # my_result= “{90,0,0,90,0,0}”

point my_point = {100,200,300,90,0,0}

str my_result = to_str_raw(my_point) # my_result=“100,200,300,90,0,0”

joint my_joint = {90,0,0,90,0,0}

str my_result = to_str_raw(my_joint) # my_result= “90,0,0,90,0,0”3.9 s = to_str_int(v)

Converts a single number to a string of integers.

Input :

Single string type variable or constant string.

s: string type variable or constant stringReturn :

s: return string

Example :

var my_value = 123.45

str my_result = to_str_int(my_value) # my_result= “123”3.10 a = str_parse(s, s, s, s)

Parses a string containing header and tail and stores it in the form of a numeric array.

Input :

s: Source string. string type variable or constant string

s: Header string. string type variable or constant string

s: Tail string. string type variable or constant string

s: Separator string. string type variable or constant stringReturn :

a: return array type

Example :

str my_source_str = “S43,22,31,44,-5”

var my_result = str_parse(my_source_str, “S”, “”, “,”)

# my_result[0] = 5 // number of elements

# my_result[1] = 43, my_result[2] = 22, my_result[3] = 31, my_result[4] = 44, my_result[5] = -5

str my_source_str = “S{43/22/31/44}E”

var my_result = str_parse(my_source_str, “S{”, “}E”, “/”)

# my_result[0] = 4 // number of elements

# my_result[1] = 43, my_result[2] = 22, my_result[3] = 31, my_result[4] = 44

str my_source_str = “-100,200,-300”

var my_result = str_parse(my_source_str, “”, “”, “,”)

# my_result[0] = 3 // number of elements

# my_result[1] = -100, my_result[2] = 200, my_result[3] = -300

str my_source_str = “STX-100$200$-300ETX”

var my_result = str_parse(my_source_str, “STX”, “ETX”, “$”)

# my_result[0] = 3 // number of elements

# my_result[1] = -100, my_result[2] = 200, my_result[3] = -3004. Bit Functions

4.1 v = get_bit(v, v)

A function that obtains the bit of a specific bit position from a variable or constant.

Input :

Two variable types or constant numbers

v: Target variable or number for the bit aquisition.

v: Target bit index (position). Bit index is starting from 0.Return :

v: Bit value (0 or 1)

Example :

# 1234 = 0b10011010010

var my_bit = get_bit(1234, 3) # my_bit= 04.2 set_bit(v, v)

This is a function that changes the bit at a specific bit position in variable to 1.

Input :

Two variable types or constant numbers

v: Target variable or number for the bit set

v: Target bit index (position). Bit index is starting from 0.Return :

None.

Example :

var my_var = 1234 # 1234 = 0b10011010010

set_bit(my_var, 3) # my_var= 12424.3 clear_bit(v, v)

This is a function that changes the bit at a specific bit position in variable to 0.

Input :

Two variable types or constant numbers

v: Target variable or number for the bit clear

v: Target bit index (position). Bit index is starting from 0.Return :

None.

Example :

var my_var = 1234 # 1234 = 0b10011010010

clear_bit(my_var, 1) # my_var= 12324.4 <<, >>, &, |

Bit shift operators, Bit and / or operators

Can use when bit-shifting or bit and/or operation.

Example :

Var my_num = 12 # my_num = 0b1100

Var my_num2 = my_num << 2 # my_num2 = 48 (0b110000)5. System Functions

5.1 halt

Stop any program flow or action/movement.

Example :

halt5.2 task stop

Stop any program flow or action/movement.

Example :

task stop5.3 mc jall init

Apply DC power to the robot arm and turn the servo-on to activate it. (Activation)

5.4 pgmode real

Switch the robot's operating mode to 'Real-Robot'.

5.5 pgmode simulation

Switch the robot's operating mode to Simulation'.

5.6 program_load_and_run(s)

Load and Run the target project/program

Input :

s: Name of the target project in string type.Return :

None.

Example :

program_load_and_run(“my_project”)

program_load_and_run(“hello_world_v90”)5.7 task load your_project_name

Load saved project file

Input :

Name of project/program wsl nameReturn :

None.

Example :

task load hello_world

task load my_project_1235.8 task play once

Run/execute the loaded-program.

5.9 task stop

Stop any program flow or action/movement.

5.10 task pause

Pause the program/motion running.

5.11 task resume_a

Resume from “general pause condition”

5.12 task resume_b

Resume from “collision detection situation”

5.13 v = pattern_get_count(v)

A function to obtain the current index of the grid that is being performed by the pattern function.

Input :

Single variable type or constant number

v: Pattern number (Confirmation of assigned number is required.)

: The pattern unique number is set in the pattern action.Return :

v: Returns the current index of the grid.

Example :

var current_count = pattern_get_count(6691) # Get the current grid index of pattern number 6691.5.14 pattern_set_count(v, v)

A function that forcibly sets the index of the grid that does the work in the pattern function.

Input :

Two variable types or constant numbers

v: Pattern number (Confirmation of assigned number is required.)

: The pattern unique number is set in the pattern action.

v: Desired grid index

: If the pattern is a 2D flat pattern, and there are grid points of 3x5 = 15, the configurable indices are 0 to 14.Return :

None.

Example :

pattern_set_count(6691, 3) # Set the grid index of pattern number 6691 to 3.5.15 P = calc_fk_tcp(v, v, v, v, v, v), P = calc_fk_tcp(J)

Calculate TCP posture w.r.t. global (base) coordinate from six joint angles.

Input type 1:

Six variable types or constant numbers.

v, v, v, v, v, v: six joint angles (Unit: Degree)Input type 2:

J: Single joint type variable which contains six joint-angles.Return :

P: Point type variable which contains TCP posture w.r.t. global (base) coordinate

Example :

joint my_joint = {0,0,0,0,0,0}

point my_result = calc_fk_tcp(my_joint) # my_result= {0, -207.62, 1100.59, 0, 0, 0}

# Depending on the TCP setting or robot model, the result may be different.

point my_result = calc_fk_tcp(0,0,0,0,0,0) # Same result will be return to ‘my_result’5.16 P = calc_fk_tfc(v, v, v, v, v, v), P = calc_fk_tfc(J)

Calculate TFC (Tool Flange Center) posture w.r.t. global (base) coordinate from six joint angles.

※ The tool flange is where the gripper/tool is mounted on the robot.

Input type 1:

Six variable types or constant numbers.

v, v, v, v, v, v: six joint angles (Unit: Degree)Input type 2:

J: Single joint type variable which contains six joint-angles.Return :

P: Point type variable which contains TFC posture w.r.t. global (base) coordinate

Example :

joint my_joint = {0,0,0,0,0,0}

point my_result = calc_fk_tfc(my_joint) # my_result= {0, -207.62,1100.59,0,0,0}

point my_result = calc_fk_tfc(0,0,0,0,0,0) # Same result will be return to ‘my_result’5.17 v = point_dist(P, P)

Calculates the distance between two points.

Input :

Two Point type variables.

P: Target point 1

P: Target point 2Return :

v: return single number (distance).

Example :

point my_ptr1 = {100, 200, 300, 0, 0, 0}

point my_ptr2 = {100, 200, 200, 0, 0, 0}

var my_result = point_dist(my_ptr1, my_ptr2) # my_result= 1005.18 P = point_add(P, P)

Calculates the addition of two points.

Input :

Two Point type variables.

P: Target point 1

P: Target point 2Return :

v: Returns point, which is the result of adding two points.

Example :

point my_ptr1 = {100, 0, 300, 150, 0, 30}

point my_ptr2 = {100, 200, 300, 90, 0, 90}

point my_result = point_add(my_ptr1, my_ptr2)

# my_result= {200, 200, 600, -90, -30, -60}

# x,y,z Distance values are treated as simple arithmetic operations.

# Rx,Ry,Rz Rotation values are treated as rotation matrix operations.5.19 P = point_sub(P, P)

Calculates the subtraction of two points.

Input :

Two Point type variables.

P: Target point 1

P: Target point 2Return :

v: Returns point, which is the result of subtraction of two points.

Example :

point my_ptr1 = {100, 0, 300, 150, 0, 30}

point my_ptr2 = {100, 200, 300, 90, 0, 90}

point my_result = point_sub(my_ptr1, my_ptr2)

# my_result= {0, -200, 0, 0, 60, -60}

# x,y,z Distance values are treated as simple arithmetic operations.

# Rx,Ry,Rz Rotation values are treated as rotation matrix operations.5.20 P = point_mid(P, P)

Calculates the midpoint between two points.

Input :

Two Point type variables.

P: Target point 1

P: Target point 2Return :

P: Returns the point that is the midpoint between two points.

Example :

point my_ptr1 = {100, 0, 300, 150, 0, 30}

point my_ptr2 = {100, 200, 300, 90, 0, 90}

point my_result = point_mid(my_ptr1, my_ptr2)

# my_result= {100, 100, 300, 120, -8.21, 60}

# x,y,z Distance values are treated as simple arithmetic operations.

# Rx,Ry,Rz Rotation values are treated as rotation matrix operations.5.21 P = point_interpolate(P, P, v)

Computes the interpolation point between two points.

Input :

Two Point type variables and single variable/number are required

P: Target point 1

P: Target point 2

v: Weight factor for interpolation (0 ~ 1)Return :

P: Returns a point that is the result of interpolation between two points.

Example :

point my_ptr1 = {100, 0, 300, 150, 0, 30}

point my_ptr2 = {100, 200, 300, 90, 0, 90}

point my_result = point_interpolate(my_ptr1, my_ptr2, 0.1)

# my_result= {100, 20, 300, 144.43, -2.86, 35.37}

# x,y,z Distance values are treated as simple arithmetic operations.

# Rx,Ry,Rz Rotation values are treated as rotation matrix operations.5.22 P = point_trans_g2u(P, v)

Converts the attitude value stored in the Point variable from the global (base) coordinate system to the user coordinate system.

Input :

Single Point type variable and single number.

P: Target point

v: User coordinate number (User coordinate: 0, 1, 2)Return :

P: Returns the converted point coordinate value.

Example :

point my_global_p

point my_local_p = point_trans_g2u(my_global_p, 0)5.23 P = point_trans_u2g(P, v)

Converts the attitude value stored in the Point variable from the user coordinate system to the global (base) coordinate system.

Input :

Single Point type variable and single number.

P: Target point

v: User coordinate number (User coordinate: 0, 1, 2)Return :

P: Returns the converted point coordinate value.

Example :

point my_local_p

point my_global_p = point_trans_u2g(my_local_p, 0)5.24 P = get_tcp_info()

This function returns the TCP information of the current robot.

Input :

None.Return :

P: Returns the TCP of the current robot based on the global coordinate system. (Unit: mm & degree)

Example :

point my_result = get_tcp_info() # TCP posture information will be stored in ‘my_result’5.25 P = get_tfc_info()

This function returns the TFC (Tool flange center) information of the current robot.

Input :

None.Return :

P: Returns the TFC of the current robot based on the global coordinate system. (Unit: mm & degree)

Example :

point my_result = get_tfc_info() # TFC posture information will be stored in ‘my_result’5.26 J = joint_add(J, J)

Calculates the addition of the angles of two Joints.

Input :

Two Joint type variables

J: Target joint 1

J: Target joint 2Return :

J: Returns the joint, which is the result of the addition operation of two joints.

Example :

joint my_joint1 = {45, 15, 0, 0, 0, 90}

joint my_joint2 = {0, 45, 45, 15, 0, 0}

joint my_result = joint_add(my_joint1, my_joint2) # my_result= {45,60,45,15,0,90}5.27 J = joint_sub(J, J)

This function calculates the subtraction of two joint angles.

Input :

Two Joint type variables

J: Target joint 1

J: Target joint 2Return :

J: Returns the joint, which is the result of the subtraction operation of two joints.

Example :

joint my_joint1 = {45, 15, 0, 0, 0, 90}

joint my_joint2 = {0, 45, 45, 15, 0, 0}

joint my_result = joint_sub(my_joint1, my_joint2) # my_result= {45,-30,-45,-15,0,90}5.28 J = joint_mid(J, J)

Computes the intermediate joint between two joint angles.

Input :

Two Joint type variables.

J: Target joint 1

J: Target joint 2Return :

J: Returns the joint that is the result of the intermediate joint operation of two joints.

Example :

joint my_joint1 = {45, 15, 0, 15, 0, 90}

joint my_joint2 = {45, 15, 0, 15, 0, 0}

joint my_result = joint_mid(my_joint1, my_joint2) # my_result= {45, 15, 0, 15, 0, 45}5.29 J = joint_interpolate(J, J, v)

Computes the interpolation joint between two joint angles.

Input :

Two Joint type variables and single variable/number are required

J: Target joint 1

J: Target joint 2

v: Weight factor for interpolation (0 ~ 1)Return :

J: Returns a joint that is the result of interpolation between two joints.

Example :

joint my_joint1 = {45, 15, 0, 15, 0, 90}

joint my_joint2 = {45, 15, 0, 15, 0, 0}

joint my_result = joint_interpolate(my_joint1, my_joint2, 0.1)

# my_result= {45, 15, 0, 15, 0, 81}5.30 J = get_joint_info()

Returns the current joint angle information.

Input :

None.Return :

J: It returns the joint information of the current robot based on the joint coordinate system. (Unit: degree)

Example :

joint my_result = get_joint_info() # current robot’s joint angles will be return to ‘my_result’5.31 set_payload_info(v, v, v, v)

Set the tool payload w.r.t. the manufacturer’s default tool coordinate system.

CAUTION

- The value set in this function returns to the default value after the program ends.

- If this function is not called in program-flow, the value set in the Setup page is used.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Four variable types or constant numbers.

v: payload weight (Unit: kg)

v: payload Center of mass x-axis value (Unit: mm)

v: payload Center of mass y-axis value (Unit: mm)

v: payload Center of mass z-axis value (Unit: mm)- Three values entered are based on the manufacturer's default tool coordinate system.

Return :

None.

Example :

set_payload_info(3, 0, -50, 0) # Set payload as 3kg, and center-of-mass as (0mm,-50mm, 0mm).5.32 set_tcp_info(v, v, v, v, v, v)

Set the TCP position and orientation w.r.t. the manufacturer’s default tool coordinate system.

CAUTION

- The value set in this function returns to the default value after the program ends.

- If this function is not called in program-flow, the value set in the Setup page is used.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Six variable types or constant numbers.

v: TCP’s x-value (Unit: mm)

v: TCP’s y-value (Unit: mm)

v: TCP’s z-value (Unit: mm)

v: TCP’s Rx-value (Unit: degree)

v: TCP’s Ry-value (Unit: degree)

v: TCP’s Rz-value (Unit: degree)- Six values entered are based on the manufacturer's default tool coordinate system.

Return :

None.

Example :

set_tcp_info(0, -100, 0, 0, 0, 0) # Set TCP position as (0mm,-100mm, 0mm).5.33 set_collision_onoff(v)

This function turns on/off the collision detection function.

CAUTION

- The value set in this function returns to the default value after the program ends.

- If this function is not called in program-flow, the value set in the Setup page is used.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Single variable type or constant number

v: 0 is off , 1 is on.Return :

None.

Example :

set_collision_onoff(1) # Turn on the collision detection function.5.34 set_collision_th(v)

Sets the collision sensitivity (threshold).

CAUTION

- The value set in this function returns to the default value after the program ends.

- If this function is not called in program-flow, the value set in the Setup page is used.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Single variable type or constant number

v: Value between 0 ~ 1. The lower the value, the more sensitive to collision. (0 ~ 1)Return :

None.

Example :

set_collision_th(0.1) # Set the collision threshold as 10%.5.35 set_collision_mode(v)

Set the stop-mode after the collision detection.

CAUTION

- The value set in this function returns to the default value after the program ends.

- If this function is not called in program-flow, the value set in the Setup page is used.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Single variable type or constant number

v: Stop mode.- 0 = General Stop

- 1 = Evasion Stop

Return :

None.

Example :

set_collision_mode(1)

# After detecting a collision, the robot moves a little in the direction to avoid external force and then stops the movement.5.36 set_collision_after(v)

Set the program flow direction after the collision detection.

CAUTION

- The value set in this function returns to the default value after the program ends.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Single variable type or constant number

v: Stop mode- 0 = Pause the Program flow (default)

- 1 = Halt/Stop the Program flow

Return :

None.

Example :

set_collision_after(1) # After detecting an external collision, the program flow stops (ends).5.37 set_speed_multiply(v)

Sets the overall speed (velocity) multiplier.

CAUTION

- The value set in this function returns to the default value after the program ends.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Single variable type or constant number

v: Multiply value (0 ~ 2) (default: 1)Return :

None.

Example :

var speed_override = 1.5

set_speed_multiply(speed_override) # Desired-speed = 1.5 x original-speed5.38 set_acc_multiply(v)

Sets the overall acceleration multiplier.

CAUTION

- The value set in this function returns to the default value after the program ends.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Single variable type or constant number

v: Multiply value (0 ~ 2) (default: 1)Return :

None.

Example :

var acc_override = 0.5

set_acc_multiply(acc_override) # Desired-acceleration = 0.5 x original-acceleration5.39 set_speed_acc_j(v, v)

Sets fixed joint velocity/acceleration for J-series motions (Move J, Move JB, Move JL).

CAUTION

- The value set in this function returns to the default value after the program ends.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Two variable types or constant numbers

v: Speed/ Velocity (Unit: 𝒅𝒆𝒈/𝒔)

Does not lock the speed for negative input.

v: Acceleration (Unit: 𝒅𝒆𝒈/𝒔𝟐)

Does not lock the acceleration for negative input.Return :

None.

Example :

set_speed_acc_j(10, 3) # Ignoring the speed/acceleration set for each point of Move,

# set speed as 10 𝑑𝑒𝑔/𝑠, and acceleration as 3 𝑑𝑒𝑔/𝑠2.

set_speed_acc_j(-1, 5) # Ignoring the acceleration set for each point of Move,

# set acceleration as 5𝑑𝑒𝑔/𝑠2.5.40 set_speed_acc_l(v, v)

Sets fixed linear velocity/acceleration for L-series motions (Move L, Move PB, Move LB, Move ITPL).

CAUTION

- The value set in this function returns to the default value after the program ends.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Two variable types or constant numbers

v: Speed/ Velocity (Unit: 𝒎𝒎/𝒔)

Does not lock the speed for negative input.

v: Acceleration (Unit: 𝒎𝒎/𝒔𝟐)

Does not lock the acceleration for negative input.Return :

None.

Example :

set_speed_acc_l(15, 5) # Ignoring the speed/acceleration set for each point of Move,

# set speed as 15 𝑚𝑚/𝑠, and acceleration as 5 𝑚𝑚/𝑠2.

set_speed_acc_l(5, -1) # Ignoring the speed set for each point of Move,

# set speed as 5𝑚𝑚/𝑠.5.41 set_speed_bar(v)

Set the overall speed control bar. (bottom speed control bar in UI).

CAUTION

- When running a program on the UI Make page, this function does not work if the safety slide bar option is turned on.

Input :

Single variable type or constant number

v: Desired speed control bar position (0 ~ 1)Return :

None.

Example :

set_speed_bar(0.5) # Set the speed control bar to 50%.5.42 set_box_dout(v, v)

Set the digital output of the control box.

Input :

Two variable types or constant numbers.

v: Port number for the digital-output (0 ~ 15)

v: Output mode selection (-1 = Bypass, 0 = Low, 1 = High)Return :

None.

Example :

set_box_dout(0, 0) # Low output from port 0

set_box_dout(0, -1) # Keep low on port 0

set_box_dout(0, 1) # High output from port 0

set_box_dout(0, -1) # Keep high on port 05.43 set_box_aout(v, v)

Set the analog output of the control box.

Input :

Two variable types or constant numbers

v: Port number for the analog output (0 ~ 3)

v: Desired output voltage (0 ~ 10V)Return :

None.

Example :

set_box_aout(3, 7) # set 7V for the analog output port 3.5.44 set_box_dout_toggle(v)

Toggles the current digital output of the control box.

Input :

Single variable type or constant number

v: Port number for the digital-output (0 ~ 15)Return :

None.

Example :

set_box_dout (1, 1) # High output from port 1

set_box_dout_toggle (1) # Toggle the output port 1 ( Low signal will be out)

repeat (1 times){ # Port 3 blinks every second

set_box_dout_toggle(3)

wait (1 sec)

}5.45 set_serial_tool(v, v, v)

Set the serial communication (RS232/485) provided by the Tool Flange of the robot arm.

CAUTION

- The value set in this function returns to the default value after the program ends.

- If this function is not called in program-flow, the value set in the Setup page is used.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Three variable types or constant numbers.

v: Communication speed(Baud rate)

v: Stop bit, (0 or 1, Default 1)

v: Parity bit, (0 : none, 1 : odd, 2 : even, Default 0)Return :

None.

Example :

set_serial_tool(115200, 1, 0)

# Set tool-flange serial comm. : baud rate = 115200 / stop bit = 1 / parity = none5.46 set_serial_box(v, v, v)

Set the serial communication (RS232/485) provided by the control box.

CAUTION

- The value set in this function returns to the default value after the program ends.

- If this function is not called in program-flow, the value set in the Setup page is used.

- During program flow, the value set in this function is maintained until this function is called again.

Input :

Three variable types or constant numbers.

v: Communication speed(Baud rate)

v: Stop bit, (0 or 1, Default 1)

v: Parity bit, (0 : none, 1 : odd, 2 : even, Default 0)Return :

None.

Example :

set_serial_box(9600, 1, 0)

# Set control-box serial comm. : baud rate = 9600 / stop bit = 1 / parity = none5.47 arm_powerdown()

Turn off the power supply for the robot arm.

CAUTION

- The robot arm powers down. Be careful with use. The control box does not turn off.

Input :

None.Return :

None.

Example :

arm_powerdown()5.48 freedrive_teach_on()

Turn on direct teaching mode (Free drive mode).

CAUTION

- When this function is executed, the control mode of the robot arm is changed. Use with caution.

5.49 freedrive_teach_off()

Turn off direct teaching mode (Free drive mode).

CAUTION

- When this function is executed, the control mode of the robot arm is changed. Use with caution.

5.50 db_write(s, v)

Write variable into the DataBase

Input :

s: name of database

v: target value for writing.Return :

None.

Example :

db_write(“my_data”, 1)5.51 db_write(s, s)

Write string into the DataBase

Input :

s: name of database

s: target value for writing.Return :

None.

Example :

db_write(“my_name”, “rainbow”)5.52 v = db_read(s), s = db_read(s)

Read variable or string data from the DataBase

Input :

s: name of databaseReturn :

Variable or String

Example :

var saved_value

str saved_name

saved_valued = db_read(“my_data”)

saved_name = db_read(“my_name”)5.53 jump_to(v)

Program execution is not executed until a specific address value.

Input :

Single variable type or the constant number.

v: Address value (0~99999)Return :

None.

Example :

# Jumps through the program flow to the point where jump_here(1234) appears.

jump_to(1234)5.54 jump_here(v)

Execute the program again from this point.

CAUTION

- This function should be located at the top line (left) of the program.

Input :

Single variable type or the constant number.

v: Address value (0~99999)Return :

None.

Example :

# In the example below, the middle two ‘wait’ lines will be ignored.

jump_to(1234)

wait (1.0 sec)

wait (2.0 sec)

jump_here(1234)5.55 jump_to_line(v)

Jump to a specific line.

Input :

Single variable type or the constant number.

v: Address value (0~99999)- The line number is the number of the top line (left) of the program.

- Begin is numbered in line 0, followed by line 1, in that order.

Return :

None.

Example :

# Go to line number 2.

jump_to_line(2)5.56 jump_to_begin()

Move to the first starting line. Same effect as jump_to_line(0).

Input :

None.Return :

None.

Example :

jump_to_begin()6. System Variables

6.1 SD_TIME

SD_TIME

SD_TIMER_0, SD_TIMER_1, …, SD_TIMER_9

A variable representing time.

It can be changed to the desired value in the Set function.

Used as a timer function.

Time automatically increments with the flow of program time. (Unit: Second)

6.2 SD_J#_REF

SD_J0_REF

SD_J1_REF

SD_J2_REF

SD_J3_REF

SD_J4_REF

SD_J5_REF

Joint reference angles. (Unit: degree)

6.3 SD_J#_ANG

SD_J0_ANG

SD_J1_ANG

SD_J2_ANG

SD_J3_ANG

SD_J4_ANG

SD_J5_ANG

Joint encoder angles. (Unit: degree)

6.4 SD_J#_CUR

SD_J0_CUR

SD_J1_CUR

SD_J2_CUR

SD_J3_CUR

SD_J4_CUR

SD_J5_CUR

Joint phase current. (Unit: A)

6.5 SD_BEGIN_J#

SD_BEGIN_J0

SD_BEGIN_J1

SD_BEGIN_J2

SD_BEGIN_J3

SD_BEGIN_J4

SD_BEGIN_J5

Variable representing the joint angles set in Begin. (Unit: degree)

6.6 SD_TEMPERATURE_MC#

SD_TEMPERATURE_MC0

SD_TEMPERATURE_MC1

SD_TEMPERATURE_MC2

SD_TEMPERATURE_MC3

SD_TEMPERATURE_MC4

SD_TEMPERATURE_MC5

Joint motor controller temperature. (Unit: celsius)

6.7 SD_TCP_X

SD_TCP_X

SD_TCP_Y

SD_TCP_Z

SD_TCP_RX

SD_TCP_RY

SD_TCP_RZ

TCP values (position and orientation) with respect to the base (global) coordinate.

6.8 SD_DEFAULT_SPEED

Representing the default speed bar. The UI speed control bar value is displayed between 0 and 1.

6.9 SD_ROBOT_STATE

Indicates whether the robot motion command is being executed.

- 1 = Idle

- 3 = Moving

6.10 SD_POWER_STATE

Power information of the control box.

- SD_POWER_STATE >> 0 & 0x01 : 48V SMPS State

- SD_POWER_STATE >> 1 & 0x01 : Power switching information

- SD_POWER_STATE >> 2 & 0x01 : 24V SMPS State

- SD_POWER_STATE >> 3 & 0x01 : 48V switching information

- SD_POWER_STATE >> 4 & 0x01 : User (PC) power selection information

- SD_POWER_STATE >> 5 & 0x01 : Estop switch state

6.11 SD_COLLISION_DETECT_STATE

Whether the external collision detection function is on/off

- 0 = Collision detection mode off

- 1 = Collision detection mode on

6.12 SD_IS_FREE_DRIVE_MODE

Whether to use direct teaching

- 0 = Free-drive (Direct teaching) off

- 1 = Free-drive (Direct teaching) on

6.13 SD_PG_MODE

Indicates the robot's operation mode.

- 0 = Real mode

- 1 = Simulation mode

6.14 SD_INIT_STATE_INFO

This is a system variable representing the activation phase information of the robot.

6.15 SD_INIT_ERR

This is a system variable that indicates the robot activation error information.

6.16 SD_TFB_ANALOG_IN_#

SD_TFB_ANALOG_IN_0

SD_TFB_ANALOG_IN_1

Variable with analog value (0~10V) of two analog input ports of tool flange board (TFB).

6.17 SD_TFB_DIGITAL_IN_#

SD_TFB_DIGITAL_IN_0

SD_TFB_DIGITAL_IN_1

A variable with a digital value (0 or 1) of the two digital input ports on the tool flange board (TFB).

6.18 SD_TFB_DIGITAL_OUT_#

SD_TFB_DIGITAL_OUT_0

SD_TFB_DIGITAL_OUT_1

A variable with an output value (0 or 1) of the two digital output ports of the tool flange board (TFB).

6.19 SD_TFB_VOLTAGE_OUT

It is a variable indicating the voltage output information (0 or 12 or 24V) of the tool flange board (TFB).

6.20 SD_OP_STAT_COLLISION_OCCUR

A variable indicating whether an external collision detected.

- 0 = Idle

- 1 = External collision detected

6.21 SD_OP_STAT_SOS_FLAG

A variable indicating if a control box power problem / robot joint controller / other problem has occurred.

- 0 = Idle

6.22 SD_OP_STAT_SELF_COLLISION

A variable indicating just before self-collision during robot motion.

- 0 = Idle

- 1 = Entering self-collision range

6.23 SD_OP_STAT_ESTOP_OCCUR

This is a variable indicating whether the program/robot is in the paused state.

- 0 = Idle

- 1 = Pause state

6.24 SD_OP_STAT_EMS_FLAG

This variable tells the user whether or not a singularity (= there is no solution for the robot control algorithm) is present.

- 0 = Idle

6.25 SD_DIGITAL_IN_CONFIG_#

SD_DIGITAL_IN_CONFIG_0

SD_DIGITAL_IN_CONFIG_1

Shows the information of the two protective stop terminals. (Din 16/17)

6.26 SD_INBOX_TRAP_FLAG_#

SD_INBOX_TRAP_FLAG_0

SD_INBOX_TRAP_FLAG_1

This is a variable that checks whether a specific part of the robot has entered a specific area (Inbox).

6.27 SD_INBOX_CHECK_MODE_#

SD_INBOX_CHECK_MODE_0

SD_INBOX_CHECK_MODE_1

Inbox Check mode.

- 0: No checking

- 1: Check Tool Flange Center (check whether the TFC is in the Inbox area)

- 2: Check Tool Center Point (check whether the TCP is in the Inbox area)

- 3: Check Tool Box (Check whether the virtual box set at the end of the robot arm has entered in Inbox area.)

- 4: Check All (1,2,3)

6.28 SD_SOCK_IS_OPEN_#

SD_SOCK_IS_OPEN_0

SD_SOCK_IS_OPEN_1

SD_SOCK_IS_OPEN_2

SD_SOCK_IS_OPEN_3

SD_SOCK_IS_OPEN_4

This is a variable indicating whether the socket of the corresponding number was normally opened and whether it was normally connected to the server.

1 (true) if creation and connection were performed normally. (# : 0 ~ 4)

6.29 SD_SOCK_LAST_READ_#

SD_SOCK_LAST_READ_0

SD_SOCK_LAST_READ_1

SD_SOCK_LAST_READ_2

SD_SOCK_LAST_READ_3

SD_SOCK_LAST_READ_4

A variable indicating whether the read function was performed normally with the socket of the corresponding number.

1 (true) if the read was performed normally. (# : 0 ~ 4)

6.30 SD_HAND_TOKTOK

This is a variable indicating whether or not an act of tapping (tok tok) from outside the robot has occurred.

6.31 SD_FINISH_AT_EVENT

Stores whether the motion has ended in a way that the robot's FinishAt (motion escape) condition.

If the motion is finished by reaching the motion target point, this variable is 0.

If the FinishAt condition is satisfied and the operation is finished, this variable becomes 1.

6.32 SD_TCP_VEL_REF

TCP reference velocity.

6.33 SD_MOTION_TIME

It is a variable that stores the time of unit movement. When the next movement is executed, it starts from 0 again.

6.34 SD_ARM_POWER

A variable representing the power the robot is using.

6.35 SD_IS_TPU_CONNECT

This is a variable that indicates whether the TPU (Teaching Pendant Unit, Tablet PC) is connected.

6.36 SD_IS_RUN_IN_MAKE

1 is saved if the current program operation is executed in the Make page.

6.37 SD_IS_RUN_IN_PLAY

1 is saved if the current program operation is executed in the Play page.

6.38 SD_IS_INTENDED_STOP

Indicates whether the program termination is an intentional termination or an emergency termination.

6.39 SD_MOVE_INDEX

In a continuous motion such as Move PB / ITPL, it tells which point the robot is passing through.

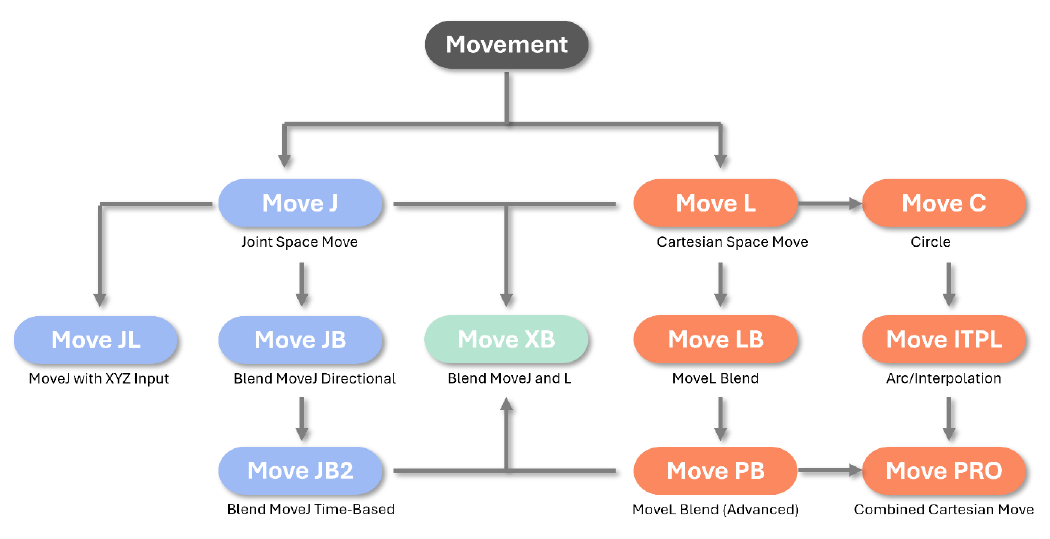

7. Movement Functions

Pre-Defined Motion Primitives

- Move J

- Move L

- Move JB

- Move JB2

- Move LB

- Move PB

- Move ITPL

- Move PRO

- Move XB

- Move Circle

User-Generate-RT Motion

- Servo J

- Servo L

- Servo T

- Speed J

- Speed L

7.1 move_finish_wait()

A function that waits for the currently executing movement to complete.

Input :

None.Return :

None.

Example :

# Wait for the movement to complete until my_destination.

point my_destination = {100,200,300,0,0,0}

move_l(my_destination, 20, 5, 0)

move_finish_wait()7.2 move_l(P, v, v, v=1)

A function that makes TCP to move in a straight line to the target point.

Input :

P: Target TCP posture

v: Speed (𝒎𝒎/𝒔)

v: Acceleration (𝒎𝒎/𝒔𝟐)

v: Wait flag (default: 1)- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,200,300,0,0,0}

point my_point2= {100,150,100,0,90,0}

move_l(my_point1, 20, 5) # Move L method to move to my_point1.

move_l(my_point2, 20, 5) # Move L method to move to my_point2.7.3 move_l_rel(P, v, v, v, v=1)

A function that makes TCP to move in a straight line to the target point.

Enter the target point as a value relative to the current TCP value.

Input :

P: Relative position & orientation value.

v: Speed (𝒎𝒎/𝒔)

v: Acceleration (𝒎𝒎/𝒔𝟐)

v: reference frame for the relative P value.0: Base (Global) coordinate.

1: Tool (Local) coordinate.

2: User coordinate 0

3: User coordinate 1

4: User coordinate 2

v: Wait flag (default: 1)

0 = No Wait (Non-Block).

1 = Wait for the movement to complete (Block).

Return :

None.

Example :

# move TCP (0,100,-200) w.r.t. Base coordinate (speed/acceleration = 300 / 400)

move_l_rel(pnt[0,100,-200,0,0,0], 300, 400, 0)

# move TCP 50 mm w.r.t. x axis of User coordinate 2 (speed/acceleration = 100 / 300)

move_l_rel(pnt[50,0,0,0,0,0], 100, 300, 4)7.4 move_j(J, v, v, v=1)

Move the robot arm to the target joint angle.

Input :

J: Target joint angles

v: Speed (Unit: 𝒅𝒆𝒈/𝒔)

v: Acceleration (Unit: 𝒅𝒆𝒈/𝒔𝟐)

v: Wait flag (default: 1)- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

move_j (jnt[0,0,90,0,90,0], 60, 80) # move joint angles to (0,0,90,0,90,0) degree with speed/acceleration = 60/80.

jnt my_joint_angle = {0,0,90,0,90,0}

move_j (my_joint_angle, 60, 80) # move joint angles to (0,0,90,0,90,0) degree with speed/acceleration = 60/80.7.5 move_j_rel(J, v, v, v=1)

Relatively move joints from its current posture.

Input :

J: Delta Target joint angles

v: Speed (Unit: 𝒅𝒆𝒈/𝒔)

v: Acceleration (Unit: 𝒅𝒆𝒈/𝒔𝟐)

v: Wait flag (default: 1)- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

# move joints (0,0,90,0,90,0) degree with speed/acceleration = 60/80. w.r.t. current posture

move_j_rel (jnt[0,0,90,0,90,0], 60, 80)

# move joints (0,0,90,0,90,0) degree with speed/acceleration = 60/80. w.r.t. current posture

jnt del_joint_angle = {0,0,90,0,90,0}

move_j_rel (del_joint_angle, 60, 80)7.6 move_jl(P, v, v, v=1)

(move joint with linear input)

This function moves to the target point using the move_j method rather than a straight line.

Input :

P: Target TCP posture

v: Speed (Unit: 𝒅𝒆𝒈/𝒔)

v: Acceleration (Unit: 𝒅𝒆𝒈/𝒔𝟐)

v: Wait flag (default: 1)- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,200,300,0,0,0}

point my_point2 = {100,150,100,0,90,0}

move_jl(my_point1, 20, 5) # Move TCP to ‘my_point1’ via Move J method.

move_jl(my_point2, 20, 5) # Move TCP to ‘my_point2’ via Move J method.7.7 move_pb_clear()

Initialize (Clear) the point list to be used in Move PB.

Input :

None.Return :

None.

Example :

move_pb_clear() # Initialize (Clear) the point list to be used in Move PB.7.8 move_pb_add(P, v, v, v)

This function adds the points used in Move PB to the list.

Input :

P: Target TCP posture

v: Speed (Unit: 𝒎𝒎/𝒔)

v: Blending option- 0 = Blend based on Ratio.

- 1 = Blend based on Distance.

v: Blending value (0 ~ 1 / distance (mm))

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

# add ‘my_point1’ to the Move PB list with speed=50mm + 50% blending option

move_pb_add(my_point1, 50, 0, 0.5)

# add ‘my_point2’ to the Move PB list with speed=100mm + 50mm blending option

move_pb_add(my_point2, 100, 1, 50)7.9 move_pb_run(v, v, v=1)

This function executes Move PB using the points added in move_pb_add.

Input :

v: Acceleration (Unit: 𝒎𝒎/𝒔𝟐 )

v: Orientation option- 0 = Intended (Follows the rotation value taught by the user)

- 1 = Constant (Keep the rotation value of the starting position)

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

move_pb_clear() # Clear the Move PB list.

move_pb_add(my_point1, 50, 0, 0.5) # add the desired point to the list (my_point1)

move_pb_add(my_point2, 100, 1, 50) # add the desired point to the list (my_point2)

move_pb_run(200, 1) # Move to my_point2 using the previously set blending options.

# At this time, the rotation value maintains the same value as the starting position.7.10 move_itpl_clear()

Initialize (Clear) the point list to be used in Move ITPL.

Input :

None.Return :

None.

Example :

move_itpl_clear() # Initialize (Clear) the point list to be used in Move ITPL.7.11 move_itpl_add(P, v)

This function adds the points used in Move ITPL to the list.

Input :

P: Target TCP posture.

v: Speed (Unit: 𝒎𝒎/𝒔)Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

# add ‘my_point1’ to the Move ITPL list with speed=50mm

move_itpl_add(my_point1, 50)

# add ‘my_point2’ to the Move ITPL list with speed=100mm

move_itpl_add(my_point2, 100)7.12 move_itpl_run(v, v, v=1)

This function executes Move ITPL using the points added in move_itpl_add.

Input :

v: Acceleration

v: Orientation/motion option- 0 = Intended (Follows the rotation value taught by the user)

- 1 = Constant (Keep the rotation value of the starting position)

- 2 = Reserved (N/A)

- 3 = Smooth (Similar to Intended, but with a smooth rate of rotation change)

- 4 = Reserved (N/A)

- 5 = CA-Intended (CA mode Intended)

- 6 = CA-Constant (CA mode Constant)

- 7 = Reserved (N/A)

- 8 = CA-Smooth (CA mode Smooth)

CA: Combined Arc mode

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

move_itpl_clear() # Clear the Move ITPL list

move_itpl_add(my_point1, 50) # add ‘my_point1’ to the Move ITPL list with speed = 50mm/s

move_itpl_add(my_point2, 100) # add ‘my_point2’ to the Move ITPL list with speed = 100mm/s

move_itpl_run(200, 1) # Move to ‘my_point2’ with move_itpl type movement.

# In this case, the rotation value taught by the user is used.7.13 move_pro_clear()

Initialize (Clear) the point list to be used in Move Pro.

Input :

None.Return :

None.

Example :

# Initialize (Clear) the point list to be used in Move Pro.

move_pro_clear()7.14 move_pro_add(P, v, v, v)

This function adds the points used in Move Pro to the list.

Input :

P: Target TCP posture

v: Speed (Unit: 𝒎𝒎/𝒔)

v: Point Type- 0 = Linear

- 1 = Corner (Circle)

- 2 = Blend(dist)

- 3 = Blend (%)

v: Blending value (used for type 2 and 3)

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

# add ‘my_point1’ to the Move Pro list with speed=50mm as Linear-Waypoint

move_pro_add(my_point1, 50, 0, 0)

# add ‘my_point2’ to the Move PB list with speed=100mm as Circular(Corner)-Waypoint

move_pro_add(my_point2, 100, 1, 0)7.15 move_pro_run(v, v, v=1)

This function executes Move Pro using the points added in move_pro_add.

Input :

v: Acceleration (Unit: 𝒎𝒎/𝒔𝟐 )

v: Orientation option- 0 = Intended (Follows the rotation value taught by the user)

- 1 = Constant (Keep the rotation value of the starting position)

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

# Clear the Move Pro list.

move_pro_clear()

# add the desired point to the list (my_point1) - Linear

move_pro_add(my_point1, 50, 0, 0)

# add the desired point to the list (my_point2) - Circular (Corner)

move_pro_add(my_point2, 100, 1, 0)

# add the desired point to the list - Linear

move_pro_add(pnt[150, 0, 400,0,0,0], 100, 0, 0)

move_pro_run(200, 0)7.16 move_xb_clear()

Initialize (Clear) the point list to be used in MoveXB (Blend L and J).

Input :

None.Return :

None.

Example :

# Initialize (Clear) the point list to be used in MoveXB.

move_xb_clear()7.17 move_xb_add(P, v, v, v, v)

This function adds the points used in MoveXB to the list. (L-Type Movement)

Input :

P: Target TCP posture

v: Speed (Unit: 𝒎𝒎/𝒔)

v: Acceleration (Unit: 𝒎𝒎/𝒔𝟐)

v: Blend Type (0 = Blend in %, 1 = Blend in mm)

v: Blending value (based on Blend Type % or mm)Return :

None.

Example :

move_xb_add(pnt[100,200,300,90,0,90], 100, 400, 0, 100)7.18 move_xb_add(J, v, v, v, v)

This function adds the points used in MoveXB to the list. (J-Type Movement)

Input :

J: Target Joint posture

v: Speed (Unit: %)

v: Acceleration (Unit: %)

v: Blend Type (0 = Blend in %, 1 = Blend in mm)

v: Blending value (based on Blend Type % or mm)Return :

None.

Example :

move_xb_add(jnt[0,0, 90,0,90,0], 50, 40, 0, 100)7.19 move_xb_run(v, v=1)

This function executes MoveXB using the points added in move_xb_add.

Input :

v: Trajectory Blending Option- 0 = Speed blending

- 1 = Position blending

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

move_xb_clear()

move_xb_add(pnt[100,200,300,90,0,90], 100, 400, 0, 100)

move_xb_add(jnt[0,0, 90,0,90,0], 50, 40, 0, 100)

move_xb_run(0, 0)7.20 move_lc_clear()

Initialize (Clear) the point list to be used in Move LC.

Input :

None.Return :

None.

Example :

move_lc_clear() # Initialize (Clear) the point list to be used in Move LC.7.21 move_lc_add(P, v, v)

This function adds the points used in Move LC to the list.

Input :

P: Target TCP posture.

v: Speed (Unit: 𝒎𝒎/𝒔)

v: Property (0 or 1)- 0 = Pass through linear motion

- 1 = Pass through circular motion

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

move_lc_add(my_point1, 50, 1) # add ‘my_point1’ to the Move LC list with velocity 50mm/s.

move_lc_add(my_point2, 100, 0) # add ‘my_point2’ to the Move LC list with velocity 100mm/s.7.22 move_lc_run(v, v, v=1)

This function executes Move LC using the points added in move_lc_add.

Input :

v: Acceleration

v: Orientation options- 0 = Intended (Follows the rotation value taught by the user)

- 1 = Constant (Keep the rotation value of the starting position)

- 2 = Reserved (N/A)

- 3 = Smooth (Similar to Intended, but with a smooth rate of rotation change)

- 4 = Reserved (N/A)

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

move_lc_clear() # clear the Move LC list

move_lc_add(my_point1, 50, 1) # add ‘my_point1’ to the list

move_lc_add(my_point2, 100, 0) # add ‘my_point2’ to the list

move_lc_run(200, 1) # Use the linear & circular motion to move up to my_point2.

# In this case, the rotation value taught by the user is used for the rotation value.7.23 move_lb_clear()

Initialize (Clear) the point list to be used in Move LB.

Input :

None.Return :

None.

Example :

move_lb_clear() # Initialize (Clear) the point list to be used in Move LB.7.24 move_lb_add(P, v)

This function adds the points used in Move LB to the list.

Input :

P: Target TCP posture.

v: Blend distance (Unit (mm))

※ Unlike Move PB, it does not support ratio blending.Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

move_lb_add(my_point1, 20) # add ‘my_point1’ to the Move LB list + blending distance = 20mm

move_lb_add(my_point2, 20) # add ‘my_point2’ to the Move LB list + blending distance = 20mm7.25 move_lb_run(v, v, v, v=1)

This function executes Move LB using the points added in move_lb_add.

Input :

v: Speed (Unit: 𝒎𝒎/𝒔)

v: Acceleration (Unit: 𝒎𝒎/𝒔𝟐)

v: Orientation options- 0 = Intended (Follows the rotation value taught by the user)

- 1 = Constant (Keep the rotation value of the starting position)

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,200,0,0,0,0}

point my_point2 = {150,0,50,0,0,0}

move_lb_clear() # clear Move LB list.

move_lb_add(my_point1, 20) # add ‘my_point1’ to the Move LB list.

move_lb_add(my_point2, 20) # add ‘my_point2’ to the Move LB list.

move_lb_run(50, 20, 1) # Move to ‘my_point2’ using the previously set distance 20mm blending option.

# At this time, the rotation value maintains the same value as the starting position.7.26 move_c_points(P, P, v, v, v, v=1)

This function performs a movement that draws an arc through via & target points.

Input :

P: via Point TCP posture

P: target Point TCP posture

v: Speed (Unit: 𝒎𝒎/𝒔)

v: Acceleration (Unit: 𝒎𝒎/𝒔𝟐)

v: Orientation options- 0 = Intended (Follows the rotation value taught by the user)

- 1 = Constant (Keep the rotation value of the starting position)

- 2 = Radial (Rotate the TCP according to the rotation of the circle)

- 3 = Smooth (Similar to Intended, but with a smooth rate of rotation change)

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point1 = {100,100,300,0,90,0}

point my_point2 = {200,200,200,0,90,45}

move_c_points(my_point, my_point2, 50, 10, 2)

# Using ‘my_point1’ as a via-waypoint, it moves in an arc to ‘my_point2’.

# Based on the center point of the rotation, the orientation of the TCP is changed together.7.27 move_c_axis(P, v, v, v, v, v, v, v, v=1)

This function performs an arc movement using the rotation center and rotation axis information.

Input :

P: Center of the rotation (Unit: mm)

v: rotation axis’s x axis vector

v: rotation axis’s y axis vector

v: rotation axis’s z axis vector

v: rotation angle (Unit: deg)

v: Speed (Unit: 𝒎𝒎/𝒔)

v: Acceleration (Unit: 𝒎𝒎/𝒔𝟐)

v: Rotation options- 0 = Intended (rotate the same way as the Constant below.)

- 1 = Constant (Keep the rotation value of the starting position)

- 2 = Radial (Rotate the TCP according to the rotation of the circle)

v: Wait flag (default: 1)

- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

point my_point = {200,200,200,0,0,0}

move_c_axis(my_point, 1, 0, 0, 180, 50, 10, 2)

# Rotate 180 degrees around the x-axis. Center of rotation is ‘my_point’.

# Based on the center point of the rotation, the orientation of the TCP is changed together.7.28 move_jb_clear()

Initialize (Clear) the point list to be used in Move JB.

Input :

None.Return :

None.

Example :

move_jb_clear() # Initialize (Clear) the point list to be used in Move JB.7.29 move_jb_add(J)

This function adds the joint-angles used in Move JB to the list.

Input :

J: Target joint anglesReturn :

None.

Example :

jnt my_joint1 = {0, 0,0,0,0,0}

jnt my_joint2 = {90,30,15,0,0,0}

move_jb_add(my_joint1) # add ‘my_joint1’ to the Move JB list.

move_jb_add(my_joint2) # add ‘my_joint2’ to the Move JB list.7.30 move_jb_run(v, v, v=1)

This function executes Move JB using the points added in move_jb_add.

Input :

v: Speed (𝒅𝒆𝒈/𝒔)

v: Acceleration (𝒅𝒆𝒈/𝒔𝟐)

v: Wait flag (default: 1)- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

jnt my_joint1 = {0, 0,0,0,0,0}

jnt my_joint2 = {90,30,15,0,0,0}

move_jb_clear() # Clear the Move JB list.

move_jb_add(my_joint1) # add ‘my_joint1’ to the Move JB list.

move_jb_add(my_joint2) # add ‘my_joint2’ to the Move JB list.

move_jb_run(50, 20) # Moves smoothly without stopping to the previously set joint angles.7.31 move_jb2_clear()

Initialize (Clear) the point list to be used in Move JB2 (Time-based Blending).

Input :

None.Return :

None.

Example :

# Initialize (Clear) the point list to be used in Move JB2.

move_jb2_clear()7.32 move_jb2_add(J, v, v, 0, v)

This function adds the joint-angles used in Move JB2 to the list.

Input :

J: Target joint angles

v: Speed (𝒅𝒆𝒈/𝒔)

v: Acceleration (𝒅𝒆𝒈/𝒔𝟐)

0: dummy

v: Blending Rate (%)Return :

None.

Example :

jnt my_joint1 = {0, 0,0,0,0,0}

jnt my_joint2 = {90,30,15,0,0,0}

# add ‘my_joint1’ to the Move JB2 list. (with 50% blend rate)

move_jb2_add(my_joint1, 60, 80, 0, 50)

# add ‘my_joint2’ to the Move JB2 list. (with 100% blend rate)

move_jb2_add(my_joint2, 90, 100, 0, 100)7.33 move_jb2_run( v=1)

This function executes Move JB2 using the points added in move_jb_add2.

Input :

v: Wait flag (default: 1)- 0 = No Wait (Non-Block).

- 1 = Wait for the movement to complete (Block).

Return :

None.

Example :

jnt my_joint1 = {0, 0,0,0,0,0}

jnt my_joint2 = {90,30,15,0,0,0}

# Clear the Move JB2 list.

move_jb2_clear()

# add ‘my_joint1’ to the Move JB2 list.

move_jb2_add(my_joint1, 10, 20, 0, 100)

# add ‘my_joint2’ to the Move JB2 list.

move_jb2_add(my_joint2, 60, 80, 0, 80)

# Moves smoothly without stopping to the previously set joint angles.

move_jb2_run()7.34 Servo J

move_servo_j(jnt[j0, j1, j2, j3, j4, j5], t1, t2, gain, alpha)

- j0 ~ j5 : Desired Joint angle in degree (-360 ~ 360)

- t1 : Time to arrive at target point (t1 >= 0.002)

- t2 : Time to maintain the motion after arrival (0.02 < t2 < 0.2)

- gain : Velocity tracking rate (gain > 0)

- alpha : low-pass-filter gain. Smaller gain makes the motion smoother (0 < alpha < 1)

7.35 Servo L

move_servo_l(pnt[x, y, z, rx, ry, rz], t1, t2, gain, alpha)

- x,y,z,rx,ry,rz : Desired Cartesian posture in mm,deg unit (ZY'X'' Euler)

- t1 : Time to arrive at target point (t1 >= 0.002)

- t2 : Time to maintain the motion after arrival (0.02 < t2 < 0.2)

- gain : Velocity tracking rate (gain > 0)

- alpha : low-pass-filter gain. Smaller gain makes the motion smoother (0 < alpha < 1)

7.36 Servo T

move_servo_t(jnt[jt0, jt1, jt2, jt3, jt4, jt5], t1, t2, mode)

- jt0 ~ jt5 : Torque values in Nm unit

- t1 : Time to arrive at target point (t1 >= 0.002)

- t2 : Time to maintain the motion after arrival (0.02 < t2 < 0.3)

- mode :

0 = Absolute mode : Control torque = Input torque

1 = Relative mode 1 : Control torque = Input torque + Robot arm weight

2 = Relative mode 2 : Control torque = Input torque + Friction compensation 30%

3 = Relative mode 3 : Control torque = Input code + Robot arm weight + Friction compensation 30%

7.37 Speed J

move_speed_j(jnt[dj0, dj1, dj2, dj3, dj4, dj5], t1, t2, gain, alpha)

- dj0 ~ dj5 : Desired Joint angle speed in degree / sec(deg/s)

- t1 : Time to arrive at target point (t1 >= 0.002)

- t2 : Time to maintain the motion after arrival (0.02 < t2 < 0.2)

- gain : Speed tracking rate (gain = 1)

- alpha : Low-pass-filter gain. Smaller gain makes the motion smoother (0 < alpha < 1)

7.38 Speed L

move_speed_l(pnt[dx, dy, dz, drx, dry, drz], t1, t2, gain, alpha)

- dx,dy,dz,drx,dry,drz : Desired Cartesian posture speed in mm/s, deg/s unit (ZY'X'' Euler)

- t1 : Time to arrive at target point (t1 >= 0.002)

- t2 : Time to maintain the motion after arrival (0.02 < t2 < 0.2)

- gain : Speed tracking rate (gain > 0)

- alpha : low-pass-filter gain. Smaller gain makes the motion smoother (0 < alpha < 1)

7.39 Jog-L

jog_robot_l(mode, x speed, y speed, z speed, rx speed, ry speed, rz speed)

jog_robot_l(mode, x speed, y speed, z speed, rx speed, ry speed, rz speed, acc_rate, dec_rate)

- Mode

0: Stop

1: Global coordinate system

2: Tool coordinate system

3 ~ 5: User coordinate system 0~2 - x,y,z speed

mm/s unit (-250 ~ 250) - rx,ry,rz speed

deg/s unit (-45 ~ 45) - Acceleration/deceleration rate

Default value 1.0

Range: 0~10.0

Larger value means faster acceleration/deceleration, smaller value means slower acceleration/deceleration

7.40 Jog-J

jog_robot_j(mode, 0 speed, 1 speed, 2 speed, 3 speed, 4 speed, 5 speed)

jog_robot_j(mode, 0 speed, 1 speed, 2 speed, 3 speed, 4 speed, 5 speed, acc_rate, dec_rate)

- Mode

0: Stop

1: Robot arm joint

2: Additional axis - Speed 0~5