General Purpose Analog I/O Configuration

The following methods are recommended for high reliability.

- Use analog GND closest to I/O.

- Equipment and control box use the same GND. Analog I/O is not isolated from the robot control box.

- Use shielded or twisted-pair cable. Connect to the GND shield on the Power (J12) terminal.

| Terminal | Parameter | Min | Type | Max | Unit |

|---|---|---|---|---|---|

| Voltage mode Input | |||||

| AIx - AG | Voltage | 0 | - | 10 | V |

| AIx - AG | Resolution | - | 16 | - | Bit |

| Voltage mode Output | |||||

| AOx – AG | Voltage | 0 | - | 10 | V |

| AOx – AG | Resolution | - | 16 | - | Bit |

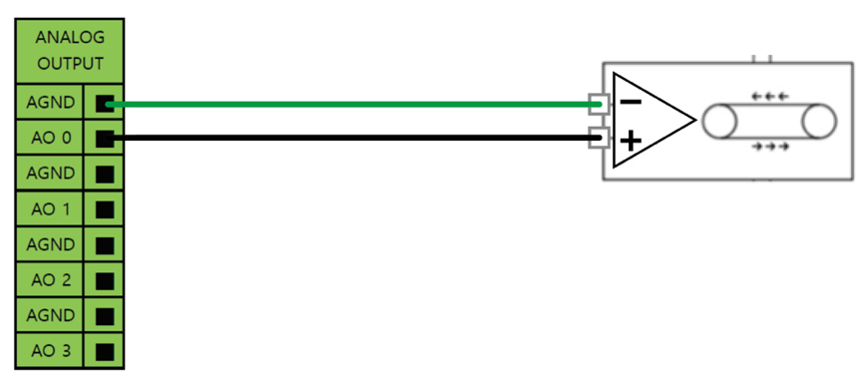

1. Analog output

The analog output can be used to control speed of conveyor. The figure below illustrates a simple demonstration.

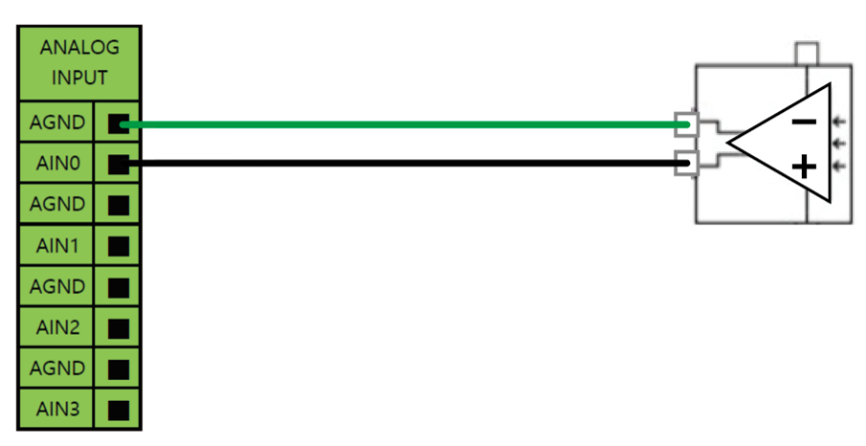

2. Analog input

The output value of the analog sensor can be used by the control box as analog input. The figure shown below illustrates a simple connection to an analog sensor.

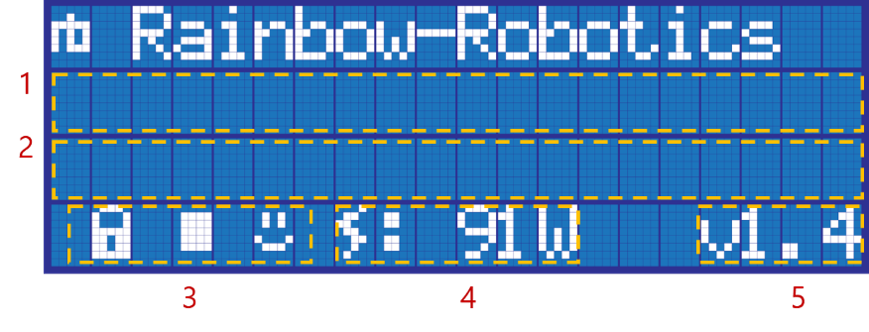

3. LCD Status Display

- Display Box(1): Displays information about system status.

- Please Wait: The main PC in the control box is booting up.

- default: The main PC in the control box is ready.

- Please Wait: The main PC in the control box is booting up.

- Display Box(2): Displays information about robot operation and status.

- Action Icon: Definition lock(

) or release(

) or release( ) state, play(

) state, play( ) or stop(

) or stop( ) state, crash(

) state, crash( ) or safe(

) or safe( )

)

state. - Power Consumption: Indicates the total power consumption in watts (W).

- System Version Information: System version information.

Rainbow Robotics

Rainbow Robotics