Maintenance of Safety Functions

In order to keep the robot in a safe state for a long time, it is necessary to continuously check the safety functions.

Safety Inspection Managers need periodic inspections for the following items.

If during the inspection you find a problem that cannot be solved by yourself, contact the manufacturer.

| Inspection target | Check List | Period | |

|---|---|---|---|

| Pendant | Safety Function | Check whether the emergency stop switch mounted on the pendant is working properly. | 1 Month |

| Cable | Check the condition of the connection cable between the pendant and the control box. | 1 Month | |

| Control Box | Interface | Check whether the EMO port to which the safety device is connected is working properly. | 1 Month |

| Check whether the PRS port to which the safety device is connected is working properly. | 1 Month | ||

| Check whether the HSS port to which the safety device is connected is working properly. | 1 Month | ||

| Check whether the SSS port to which the safety device is connected is working properly. | 1 Month | ||

| Power | Check the normal output of 24V voltage connecting the safety device. | 1 Month | |

| Check if the 24V fuse is inserted normally. | 1 Month | ||

| Cable | Check the condition of the connection cable between the safety device and the control box. | 1 Month | |

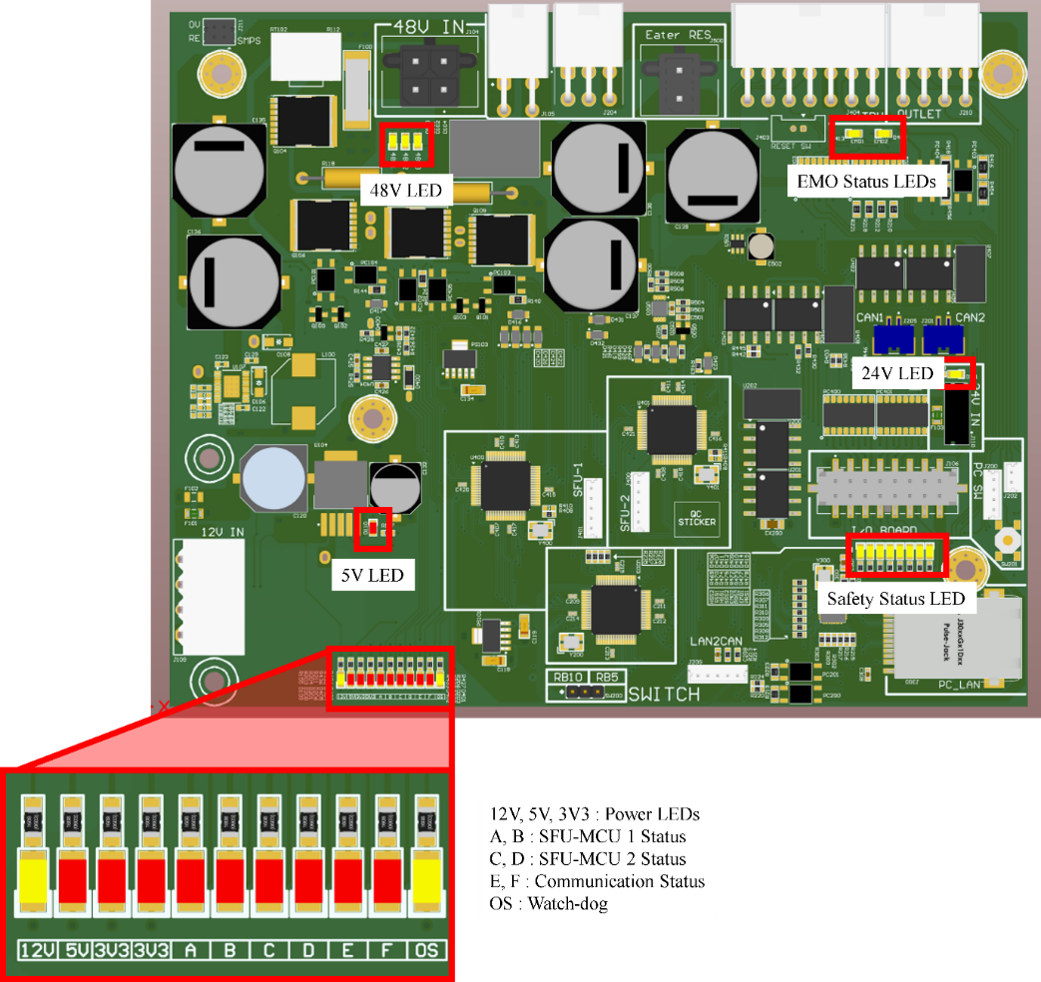

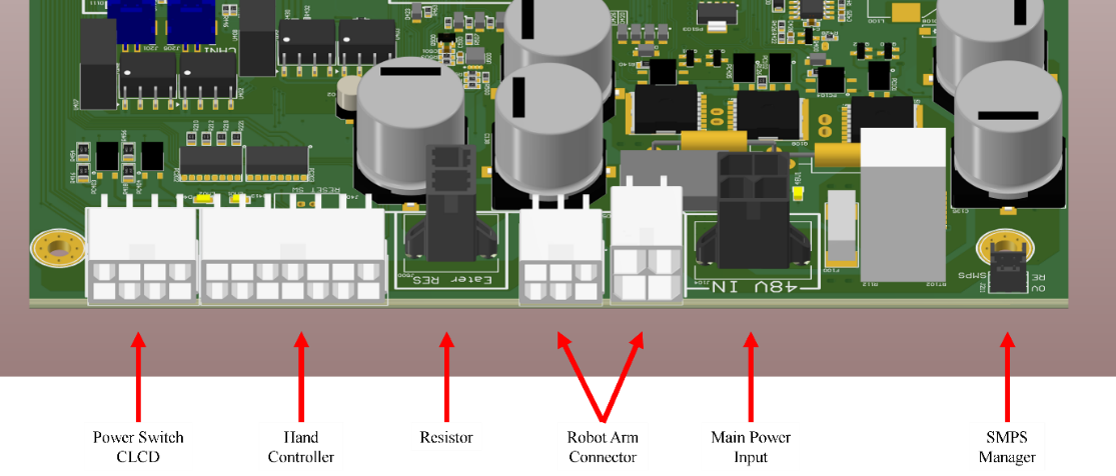

Safety Function Board Specification

Inside the control box, there is a built-in safety function board to drive the RB Series.

The information of the LED indicating the operation status of the board is as follows.

Connector information connected to the board is as follows.

Rainbow Robotics

Rainbow Robotics